In the face of the climate crisis, a growing population and changing consumer habits, traditional food production methods are becoming insufficient. This is why new technologies such as artificial meat, 3D-printed food and vertical farming are being developed. They combine science, engineering and nutrition, offering new opportunities for production, personalisation and sustainability.

ARTIFICIAL MEAT

What is artificial meat?

Artificial meat – meat that is not produced by breeding animals in the traditional way, but by cultivating animal cells in laboratory/industrial conditions.

Difference from plant-based alternatives:

Artificial meat consists of real animal cells, meat at the biological level, and is not just an imitation of taste and texture based on plant proteins.

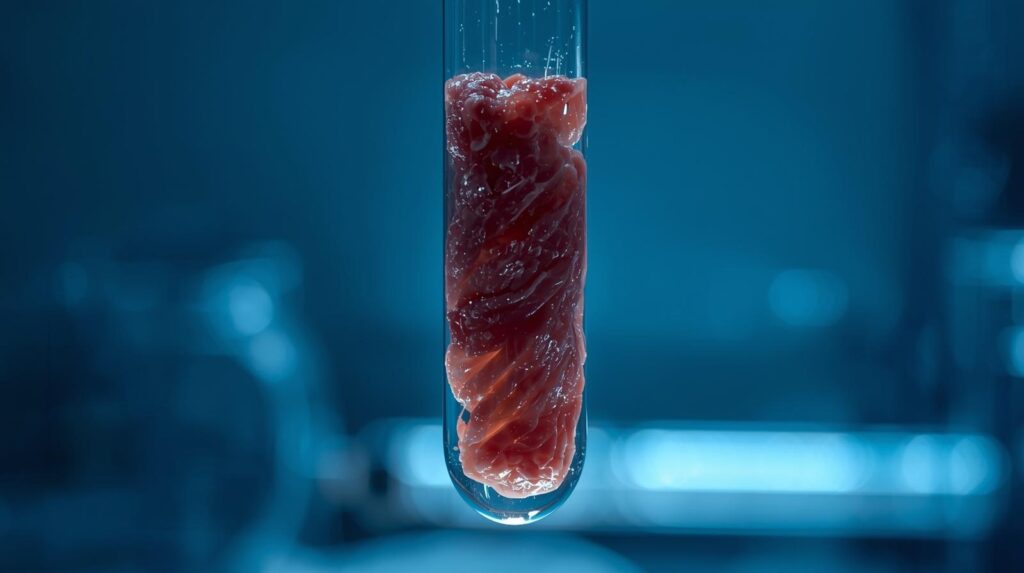

Production process:

Collection of source cells

Stem cells or satellite cells (e.g. from animal muscles) are usually collected using minimally invasive methods (e.g. biopsy).

Cell proliferation

Cells are cultivated in a so-called culture medium, i.e. a nutrient containing nutrients (amino acids, glucose, vitamins, mineral salts), growth factors and other components necessary for division and growth.

scaffolding

Cells need a support structure – this can be a biocompatible material that allows cells to attach, tissue to grow, and muscle and fat fibres to form.

- Depending on the end product (steak, nugget, minced meat), the structure of the scaffolding may be simpler or more complex.

Cell maturation/differentiation

- Cells must undergo stages of differentiation: from undifferentiated cells to muscle cells, fat cells and possibly other types (connective tissue).

- Physical conditions – temperature, pH, oxygen availability, time – must be carefully controlled.

Collection and processing of the final product

- Once the appropriate amount of cell/tissue mass has been achieved, the material is harvested, the scaffolds are usually removed if edible or separated if not, and the meat is formed/processed into end products (e.g. cutlets, nuggets, burgers, sometimes steaks).

- It can be further processed (marinated, seasoned, roasted) just like regular meat.

Scaling and industrial production

- It is then transferred to larger bioreactors (e.g. 100–1,000+ litres, ultimately much larger), where continuous flow (perfusion) systems or other innovations in bioreactors are necessary to optimise efficiency.

- Innovations in breeding media are also crucial – reducing the costs of ingredients, finding substitutes for bovine serum.

Applications – what is artificial meat used for?

➢ An alternative to traditional meat – for consumers who wish to reduce their meat consumption for ethical, environmental or health reasons.

➢ Reduction of animal suffering – no need for mass breeding and slaughter of animals.

➢ Environment/climate – lower land and water consumption; potentially lower greenhouse gas emissions compared to animal husbandry (although this depends on the energy source and technology used).

➢ Food and health safety – possibility of production in sterile conditions, lower risk of animal-borne diseases, reduced need for antibiotics.

➢ New product types – beyond minced meat/nuggets: steaks, fillets, composite products combining muscle and fat cells, blended products (e.g. a mixture of cells and plant proteins), luxury products.

Challenges and barriers

➢ Production scaling

Very large-volume bioreactors are difficult to design and maintain. Most companies operate smaller bioreactors – scaling requires technical and engineering solutions.

➢ Culture media costs and growth factors

This is one of the largest cost items. The animal-derived serum (FBS) used previously is very expensive and raises ethical concerns. Effective, inexpensive, and scalable alternatives are crucial.

➢ Structure and texture

Products such as burgers and nuggets are easier to achieve; steaks, fillets, muscle fibre texture, fat, connective tissue – these aspects require more advanced scaffolding and cell differentiation.

➢ Regulations and legislation

Artificial meat products must go through approval processes (food safety, labelling, inspections). Regulations vary from country to country. This may delay the entry of products onto the market.

➢ Social acceptance and perception

Consumers may have concerns about the taste, healthiness and naturalness of ‘test-tube meat’. Marketing, transparency and education will be important.

➢ Investment and infrastructure costs

The construction of plants, bioreactors, sterile infrastructure, control systems and raw material supplies all require large capital investments.

➢ Environmental energy costs

Although artificial meat may use less water and land, laboratory/industrial processes require energy – e.g. to maintain sterile conditions, temperature, lighting (if used), pumps, etc. Energy sources and efficiency are important here.

Current status – what has already been achieved, what is available, what are the plans

- Some companies have received regulatory approval to sell/use certain cultivated meat products. Example: Cultivated chicken (Upside Foods) in the US has received safety ratings.

- Israeli company Aleph Farms has received preliminary approval to sell cultivated beef steaks in Israel.

- Companies are working on production efficiency and scaling: for example, Believer Meats is building a large factory with a projected annual production of, among other things, farmed chicken.

- Work on animal serum substitutes and animal-free media: for example, Meatly, a UK-based company, has reduced the cost of its medium to ~£1 per litre by eliminating animal components from the medium.

Predictions for the future

Based on available data and expert analyses, several predictions can be made:

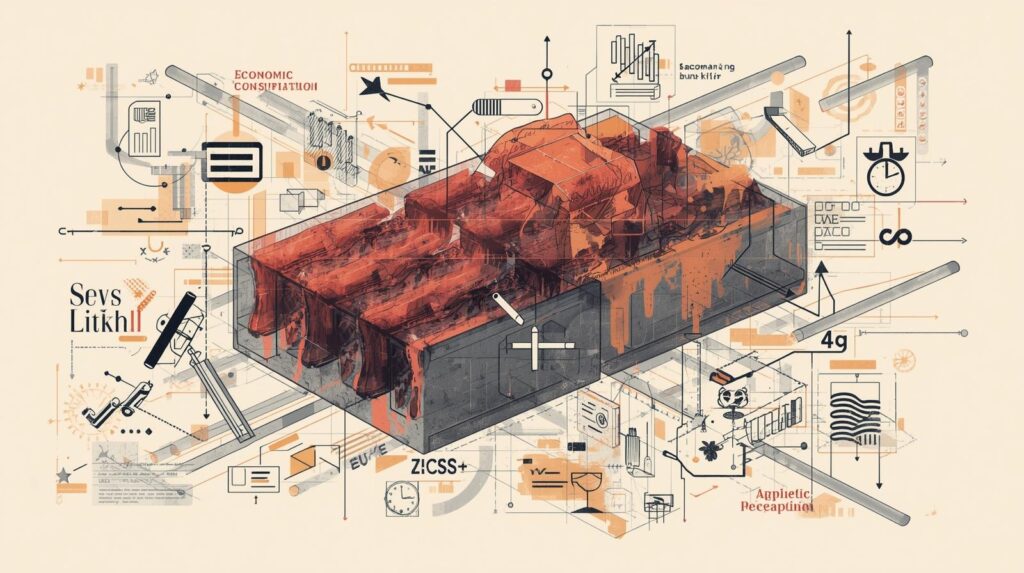

Production costs will fall significantly by 2030

TEA/LCA models predict that with sufficient scale and investment, the cost of producing cultivated meat could fall to around £4-5 per kilogram.

The retail price will approach that of traditional meat

Some segments (e.g. minced meat, chicken, nuggets) may achieve price competitiveness earlier than high-structure cuts (steak).

Luxury/speciality products first

Premium steaks, catering, niche products (e.g. animal-free food, meat for allergy sufferers) may be the first to appear before the product becomes widely available.

Regulations and standards will become crucial – cell-cultured food will have to meet sanitary and nutritional standards, as well as labelling and legal acceptance issues in different countries.

Scaling up production and infrastructure will be one of the main challenges, but also an area where huge investments will be made – building larger bioreactors, production facilities, logistics systems and raw material supply chains (e.g. culture media).

Environmental impact depends on energy source

If production is based on clean, renewable energy, the environmental benefits will be greater; if the energy comes from fossil fuels, the gains may be smaller.

Consumer acceptance and marketing – other key factors will include how the meat tastes, how it looks, how it will be promoted for sampling, and whether consumers will accept that it is farmed meat rather than ‘natural’ meat.

Potential innovations: new types of scaffolds, 3D tissue printing, better culture media, automation, better quality control, artificial intelligence systems for process optimisation.

Vertical farming — current status, applications, costs and future prospects

Vertical farming – is a method of plant production in which crops are grown in multi-layered systems (e.g. stacks of shelves, racks, modules), often in a controlled environment (inside buildings, halls, containers), without soil or with minimal soil, using hydroponics, aeroponics or other systems.

The aim is to maximise yield per unit area, shorten and simplify the supply chain, produce year-round regardless of weather conditions, minimise water and pesticide use, and save land.

How does vertical farming work?

➢ Vertical farming – based on controlled environment technology. Plants are usually grown without soil – instead, hydroponics (i.e. an aqueous solution with added nutrients), aeroponics (plants are sprayed with a nutrient mist) or special inert substrates such as mineral wool, coconut fibre or perlite are used.

➢ Plants are arranged on multi-level racks or in modular systems. Each layer is illuminated with special LED lighting that mimics natural sunlight – different wavelengths of light are adjusted to the needs of photosynthesis at different stages of growth.

➢ The environment in which the plants grow is fully controlled. This applies to temperature, humidity, carbon dioxide concentration, ventilation, as well as light intensity and duration. Thanks to sensors and automation systems, it is possible to continuously optimise conditions to ensure maximum yield and crop quality.

➢ Many vertical farms also use advanced automation systems, such as robots for planting, harvesting and packaging. Artificial intelligence and the Internet of Things (IoT) are also increasingly being used to manage the entire system.

What is vertical farming used for?

Vertical farming has many applications:

- Microgreens and sprouts – plants with high nutritional and aesthetic value, popular in restaurant cuisine.

- Medicinal herbs and functional plants – crops for the pharmaceutical and cosmetics industries.

- Local production in cities – growing crops on rooftops, in containers, in building basements, near shops and restaurants.

- Specialised production – e.g. cultivation of strawberries, cherry tomatoes or edible flowers.

- Education and scientific experiments – schools, universities and start-ups use vertical farming for research and learning.

Is vertical farming expensive?

Yes, vertical farming is currently relatively expensive – both in terms of initial investment and ongoing operating costs. At the outset, you need to invest in infrastructure, i.e. structures for placing plants, hydroponic or aeroponic systems, LED lighting, air conditioning and ventilation systems, sensors and controllers.

On top of that, there are energy costs – mainly electricity – because the entire installation runs on electricity: lighting, pumps, cooling and heating, ventilation and automation.

Although water consumption is up to 90% lower than in traditional agriculture and fertilisers are used more efficiently, the costs of maintaining the system are still high. This also applies to technical support and servicing.

In some cases, e.g. in the USA or Japan, the cost of building a single large farm can reach several million dollars.

In Poland and other European countries, the cost of building a modern vertical farm can range from several hundred thousand to several million zlotys, depending on the scale and level of sophistication.

However, thanks to technological advances and greater availability of components, prices are gradually falling, which may make this type of production more profitable within a few years.

What are the advantages of vertical farming?

Vertical farming has a number of advantages:

- Weather independence – production continues throughout the year, regardless of the season or climate.

- Significant water savings – much less water is used than in traditional farming.

- No pesticides – the environment is controlled, so infections are less common, which reduces the need for chemicals.

- Better quality and freshness – because crops can be grown close to the consumer, products are harvested just before sale.

- A shorter supply chain – means lower transport costs and fewer losses along the way.

- Sustainable development – lower CO₂ emissions, reduced consumption of natural resources, possibility of renewable energy supply.

What are the limitations and challenges?

Despite its many advantages, vertical farming is not without its problems. The biggest barriers are:

High initial costs – purchasing and installing the entire system is a significant expense.

- Energy consumption – if the farm does not use renewable energy sources, it can have a large carbon footprint.

- Limited choice of plants – deciduous plants are best suited for cultivation; root vegetables, cereals and fruit trees are difficult to adapt.

- The need for qualified personnel – systems require technical knowledge, management skills and process control.

- Difficulties in scaling – many projects struggle with profitability on a large scale. Quite a few start-ups close down after a few years of operation because their costs exceed their revenues.

What does the future hold for vertical farming?

The prospects for vertical farming are very promising. Experts predict that:

- Technology will become cheaper – advances in LEDs, automation and materials will reduce construction and operating costs.

- Vertical farms will become increasingly automated – robots and artificial intelligence will manage crops, reducing the need for human labour.

- Production will move to cities – more and more farms are being set up in city centres, on rooftops, in garages, basements and containers. Production will become more local.

- Countries can begin to support such crops through subsidies, tax breaks or environmental programmes.

- Zwiększy się różnorodność upraw – rozwój technologii pozwoli uprawiać także truskawki, pomidory

3D-printed food — a blessing or a curse?

Predictions and prospects for the development of 3D-printed food:

Medical and dietary applications will grow – especially in hospitals, nursing homes, and for people with allergies or special dietary needs.

Meal personalisation will become easier – with individual ingredients, flavours, textures and calorie counts possible.

Integration with other technologies (e.g. artificial meat, biotechnology) will enable the creation of complex, hybrid food products.

Technological advances will accelerate production — better printers, automation, AI for recipe optimisation.

Environmental potential: less waste, better use of raw materials, lower energy and transport consumption.

Definition and general idea

3D printed food is a technology that enables the creation of dishes by layering food masses (e.g. pastes, purées, gels) using special printers. It allows for shapes, structures and aesthetics that are not available in traditional cuisine.

This technology combines engineering, gastronomy and nutrition — it allows for precise control over the composition, taste and appearance of dishes. It often uses alternative ingredients, such as plant proteins or algae gels.

How it works now — processes, technologies

Ingredients:

Purées, pastes, gels or mixtures with gelling and thickening additives are used for printing. They must have the right consistency to flow through the nozzle and maintain their shape.

Printing/extrusion:

The most common method is to extrude layers through a nozzle according to a programmed design. More advanced applications also use heat treatment, lasers or structural manipulation (e.g. porosity, hardness).

Finishing:

After printing, the food may need to be heated, baked or prepared in other ways. Sometimes the products are frozen and prepared later.

Personalisation:

3D printing allows meals to be tailored to individual needs, e.g. calorie content, vitamin content, consistency for people with swallowing difficulties.

Applications — where and how 3D-printed food is used

- High-end gastronomy: Experimental restaurants often use 3D printing to create unique dishes, decorations, impressive desserts and culinary competitions. Aesthetics and uniqueness are important.

- Dietetics and medicine: People with swallowing difficulties (dysphagia) — food with the right texture that is safe to eat can be printed, while retaining its taste and nutritional content. Such projects are already in operation.

- Personalised nutrition: For athletes, hospital patients, people with allergies or intolerances — precise adjustment of macronutrients, vitamins, calories, etc. The need for individual diets.

- Special/decorative/designer products: Desserts, chocolates, sweets, luxury products, artistic forms. Also festival food, events, decorations.

The benefits of 3D-printed food

- Personalisation — you can create food that is perfectly tailored to your taste preferences, dietary requirements and health. Calories, nutrients, texture, taste, appearance — all of these can be adjusted.

- Design and aesthetics — the possibility of creating structures, shapes and appearances for dishes that would be difficult to achieve by hand; visual appeal can encourage eating, which is important in places such as hospices, care homes and restaurants.

- Texture adjustment — for elderly people, people who are ill, people with swallowing difficulties; also for those who want a specific food texture (e.g. crunchier, less crunchy).

- Potential savings and reduced waste — printing exactly the quantity needed; possibility of using less attractive raw materials or waste that would otherwise be discarded.

New culinary possibilities and innovations — creating new flavours, textures, sensory experiences (e.g. dishes that change flavour as you eat them thanks to layers and different textures), experimentation

Disadvantages, limitations and risks

- Equipment and material costs — industrial food printers are expensive; parts, food printing materials, pastes, gels, textural additives, and binding agents are also costly. For small businesses and home consumers, the investment is often too large.

- Limited compatibility of ingredients — not all ingredients are suitable for printing — they must have the right consistency, flow properties and stability after printing. Ingredients with large pieces, fibrous ingredients and ingredients that are difficult to thicken are difficult to use.

- Szybkość produkcji / skalowalność — drukowanie warstwa po warstwie jest czasochłonne; masowa produkcja żywności dla wielu konsumentów wymaga dużych nakładów czasu i zasobów; trudność w osiągnięciu efektywności na dużą skalę.

- Operating costs — energy, equipment maintenance, hygiene maintenance, system cleaning, cost of raw materials, production space.

- Social acceptance/consumer psychology — for many people, the idea of eating ‘printed’ food may be repulsive; concerns about naturalness, food processing, chemical additives; aesthetics vs. perception of ‘machine-made food’.

Modern food technologies can revolutionise the way we produce and consume food. Although they face barriers, they offer real benefits: reduced resource consumption, no animal suffering, local production, personalisation and new culinary experiences. This is a step towards a more ethical and sustainable future for food.